How Industry Connectors Improve Safety and Performance in Industrial Automation

In the era of Industry 4.0, industrial automation is transforming manufacturing, energy, transportation, and smart infrastructure. As systems become more interconnected and data-driven, the components that link these systems are increasingly critical. Among these, industry connectors play a vital role in ensuring both safety and performance.

The Role of Industry Connectors in Industrial Automation

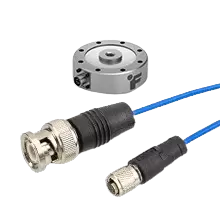

Industry connectors serve as the physical interface between electrical and electronic systems. In industrial automation, they transmit power, signals, and data between machinery, sensors, robots, and control systems. A reliable connector ensures that operations are uninterrupted, accurate, and safe, while a substandard connector can result in system failures, costly downtime, and safety hazards.

Enhancing Safety through High-Quality Connectors

Safety is paramount in industrial automation. Faulty connections can lead to short circuits, equipment malfunctions, or even industrial accidents. By using connectors that meet international standards such as IEC, GB/T, and UL, companies can significantly reduce these risks.

CAZN Electronic, a leading provider of industrial connection solutions, has established itself as a cornerstone in China’s industrial connector industry. Their products are rigorously tested to comply with global standards, ensuring reliable performance in demanding environments such as:

Wind Power: Safe transmission of high-voltage electricity in turbines.

High-Speed Rail: Secure and durable connections for communication and control systems.

Automotive Manufacturing: Reliable links in robotic assembly lines and automation equipment.

Intelligent Transportation: Stable and fail-safe connections in traffic management systems.

Smart Manufacturing: Consistent data and power transfer in smart factories.

Boosting Performance with Advanced Connectivity Solutions

Beyond safety, connectors directly influence operational efficiency. High-quality industry connectors improve performance by:

Ensuring stable signal and power transmission, reducing errors in automated systems.

Supporting high-speed data communication for real-time monitoring and control.

Withstanding harsh industrial environments, including extreme temperatures, vibration, and dust.

Simplifying maintenance and system upgrades through modular and standardized designs.

By integrating CAZN Electronic’s connectors, industrial operators can achieve smoother automation workflows, higher machine uptime, and improved overall productivity.

Industry Connectors as a Strategic Investment

Investing in reliable connectors is not just a technical choice—it is a strategic business decision. With the rapid adoption of smart factories, renewable energy, and intelligent transportation systems, the demand for safe, durable, and high-performance connectors continues to grow.

Conclusion

In industrial automation, the smallest components often have the largest impact. Industry connectors ensure that machinery, robots, and control systems communicate effectively and operate safely. By choosing trusted solutions from companies like CAZN Electronic, businesses can enhance both safety and performance, driving operational excellence and long-term reliability.

For modern industries, quality connectors are more than a link—they are the foundation of a safe, efficient, and automated future.