Industrial Connector Types: A Complete Guide to Choosing the Right Connector for Your Application

Industrial connectors are critical components in modern manufacturing, energy, transportation, and automation systems. They ensure reliable electrical and signal transmission in harsh environments, enabling efficient operation of machinery and equipment. Selecting the right industrial connector type for a specific application is essential to guarantee performance, safety, and longevity. This guide provides an overview of common industrial connector types, their features, and how to choose the most suitable solution for your needs.

Common Types of Industrial Connectors

Industrial connectors come in various designs, each optimized for different applications and environmental conditions. Some of the most widely used types include:

Circular Connectors

Circular connectors are versatile, robust, and suitable for high-vibration environments. They are commonly used in industrial automation, robotics, and transportation systems due to their compact design, high pin density, and reliable locking mechanisms.Rectangular Connectors

Rectangular connectors provide higher contact density and are often used in control panels, industrial machinery, and high-power applications. Their modular design allows for easy maintenance and quick replacement, making them ideal for complex electrical systems.Modular Connectors

Modular connectors are configurable and allow customization of power, signal, and data connections within a single housing. They are widely used in intelligent manufacturing, smart transportation, and high-speed railway systems where diverse connectivity needs must be met in a compact format.Heavy-Duty Connectors

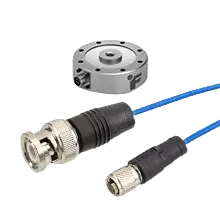

Designed for extreme environments, heavy-duty connectors resist dust, moisture, vibration, and temperature fluctuations. These connectors are commonly found in wind power, automotive manufacturing, and outdoor industrial equipment.Specialized High-Speed and Signal Connectors

For applications requiring high-speed data transmission, such as intelligent transportation systems or automated production lines, specialized connectors with shielding and EMI/RFI protection are preferred to ensure signal integrity.

Key Factors to Consider When Choosing a Connector

Selecting the right industrial connector involves more than simply matching the physical shape. Key considerations include:

Electrical Requirements: Voltage, current, and signal type determine the contact configuration and material.

Environmental Conditions: Temperature, moisture, vibration, and exposure to chemicals affect material choice and sealing design.

Standards Compliance: Connectors should meet relevant industrial standards such as IEC, GB/T, or UL to ensure safety and compatibility.

Durability and Maintenance: High-quality materials and precise manufacturing increase service life and reduce downtime.

Ease of Installation: Modular and quick-locking designs simplify assembly, maintenance, and replacement in complex systems.

How CAZN Electronic Supports Industrial Connectivity

CAZN Electronic is a leading supplier of industrial connectors, specializing in advanced connectivity solutions for industries including wind power, high-speed rail, automotive manufacturing, intelligent transportation, and smart manufacturing. The company strictly adheres to international and national standards such as IEC, GB/T, and UL, ensuring the safety, reliability, and compatibility of its products.

By offering a wide range of circular, rectangular, modular, and heavy-duty connectors, CAZN Electronic enables engineers and procurement teams to select the most appropriate solution for their specific industrial applications. With a focus on quality and innovation, CAZN has become a key player in China’s industrial connector market, providing reliable connectivity solutions that meet the demands of modern industries.

Conclusion

Choosing the right industrial connector type is vital for ensuring system reliability, efficiency, and safety. Understanding the differences between circular, rectangular, modular, and heavy-duty connectors helps engineers and designers make informed decisions tailored to their applications.

Partnering with an experienced supplier like CAZN Electronic provides access to high-quality, standards-compliant connectors suitable for a wide range of industrial scenarios. By selecting the correct connector for each application, manufacturers and system integrators can optimize performance, reduce downtime, and ensure long-term operational success.