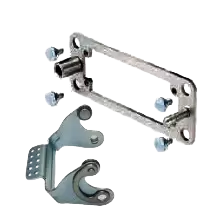

HE-016 Screw Connection HE-06-M: Reliable Termination for High-Density Industrial Connectors

In heavy-duty connector systems, failures rarely come from the connector housing itself. More often, issues originate at the termination point—loose wiring, inconsistent contact pressure, or poor vibration resistance. For industrial environments where connectors are repeatedly exposed to mechanical stress, temperature variation, and long operating cycles, the connection method inside the plug-in core becomes a decisive factor.

The HE-016 Screw Connection HE-06-M is designed to address this challenge. As part of the HE series heavy-duty connector system, it provides a stable, service-friendly screw termination solution for multi-core industrial signal and power connections.

Brand: CAZN Electronic

This article looks at the product from a wiring reliability and maintenance perspective, explaining why screw-type inserts remain a preferred choice in many industrial connector applications.

Why termination quality defines connector reliability

In industrial connectors, the plug-in core is the functional heart of the system. Even with high-quality contacts and housings, poor termination can lead to:

Increased contact resistance

Signal instability or intermittent faults

Heat buildup at connection points

Premature connector failure

For connectors used in automation, machinery, and control systems, termination reliability directly affects system uptime.

Screw connection vs other wiring methods

Multiple wiring methods exist for heavy-duty connectors, including crimp, cage clamp, and soldered termination. Screw-type wiring remains widely used due to its balance of strength, flexibility, and serviceability.

Screw connection advantages include:

Strong mechanical clamping force

Visual confirmation of proper wiring

Easy re-termination during maintenance

No special crimp tools required

For field wiring and on-site installation, screw connections offer a practical and dependable solution.

HE-016 configuration: supporting high-density wiring

The HE-016 insert provides 16 cores within a compact plug-in format. This density supports complex signal and control wiring while keeping connector size manageable.

Typical use cases include:

Multi-signal control systems

Combined power and signal transmission

Industrial I/O and automation interfaces

By consolidating multiple circuits into one connector interface, system layout becomes cleaner and easier to manage.

Male pin design for stable electrical contact

The HE-016 HE-06-M insert uses a male pin configuration, designed to provide consistent electrical contact when mated with the corresponding female insert.

From an operational standpoint, this supports:

Stable contact pressure during repeated mating cycles

Predictable electrical performance

Reduced risk of misalignment under vibration

For heavy-duty connectors, maintaining contact integrity over time is essential.

Performance in vibration and industrial environments

Industrial connectors are often installed on equipment subject to:

Continuous vibration

Mechanical shock

Thermal expansion and contraction

Screw-type termination helps maintain conductor retention under these conditions. Properly tightened screw connections resist loosening better than many alternative methods in dynamic environments.

Maintenance and troubleshooting efficiency

One key reason screw-connection inserts remain popular is maintenance accessibility.

During system upgrades or troubleshooting:

Individual wires can be re-terminated quickly

No specialized tooling is required

Visual inspection can confirm wiring condition

This reduces downtime during maintenance and simplifies field repairs—an important advantage for industrial operations.

Compliance and safety considerations

The HE-016 screw connection insert is certified to CE and RoHS standards, supporting use in regulated industrial markets.

From a compliance perspective, this helps:

Meet project and export requirements

Simplify system certification

Ensure material and manufacturing consistency

Compliance is especially important in equipment supplied to multiple regions or industries.

Typical application scenarios

The HE-016 screw connection HE-06-M insert is commonly used in:

Industrial automation equipment

Machine control panels

Power distribution and signal interfaces

Robotics and production lines

Transportation and infrastructure systems

Any application requiring reliable multi-core connectivity benefits from stable screw-type termination.

Why screw-type inserts remain relevant in modern systems

While newer termination technologies continue to emerge, screw connections remain relevant because they align with real-world installation and maintenance practices.

They are especially valuable when:

Wiring is performed on-site

System layouts change over time

Maintenance teams require flexibility

In many industrial contexts, practicality outweighs theoretical speed advantages of alternative methods.

Manufacturer perspective and connector system consistency

As an industrial connector manufacturer, CAZN Electronic focuses on providing compatible inserts, housings, and accessories within the HE series. This system approach allows users to build connector solutions tailored to their wiring density, installation method, and environmental needs.

For OEMs and system integrators, consistency across connector components reduces integration risk and simplifies long-term support.

What engineers typically confirm before selection

Before specifying a screw-connection insert, engineers usually verify:

Core count and signal requirements

Wiring method compatibility with installation process

Vibration and environmental conditions

Maintenance and re-termination needs

Certification and regulatory compliance

The HE-016 HE-06-M insert aligns well with these evaluation criteria.

A practical takeaway

The HE-016 screw connection HE-06-M is designed for industrial users who value reliable wiring, maintenance flexibility, and long-term stability. Its screw-type termination, 16-core density, and compliance certifications make it a dependable choice for heavy-duty connector systems operating in demanding environments.

For projects where downtime is costly and wiring reliability matters, screw-connection inserts continue to deliver proven value.