How to Choose the Right RF N Connector for Your Wireless or RF Application

In modern wireless and RF applications, selecting the right RF N connector is critical to ensure reliable signal transmission, minimal signal loss, and long-term system performance. Whether you are working on telecommunications, high-speed rail, wind power, automotive systems, or smart manufacturing, the correct connector can make a significant difference in efficiency and durability.

This guide provides essential considerations to help engineers and technical professionals choose the ideal RF N connector for their specific application.

1. Understand Your Frequency and Bandwidth Requirements

RF N connectors are designed to operate efficiently across specific frequency ranges. Before selecting a connector, determine:

The operating frequency of your system (commonly up to 11 GHz for standard N connectors, higher for precision versions)

Bandwidth requirements for data transmission or signal integrity

Potential interference sources in your environment

Choosing a connector compatible with your frequency ensures minimal signal degradation and optimal performance.

2. Evaluate Connector Type and Gender

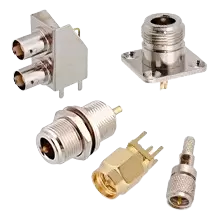

RF N connectors come in various types and configurations:

Male vs. female connectors: Ensure proper mating with existing devices or cables

Standard vs. precision types: Precision connectors provide lower VSWR (Voltage Standing Wave Ratio) for high-frequency or high-power applications

Crimp vs. solder vs. clamp style: Determines ease of installation and long-term reliability

Selecting the correct type ensures mechanical stability and secure connections in demanding environments.

3. Consider Material and Plating for Durability

The construction material and plating of an RF N connector impact both electrical performance and longevity. Look for:

High-quality brass or stainless steel bodies for mechanical strength

Gold, nickel, or silver plating for corrosion resistance and optimal conductivity

Sealed or weatherproof designs for outdoor or harsh environments

CAZN Electronic, a professional industrial connector supplier, emphasizes high-quality materials and precision manufacturing, ensuring connectors meet IEC, GB/T, and UL standards. Their connectors deliver reliable performance in wind power, high-speed rail, automotive, intelligent transportation, and smart manufacturing applications.

4. Check VSWR and Signal Loss Ratings

VSWR (Voltage Standing Wave Ratio) and insertion loss are key electrical parameters for RF connectors:

A lower VSWR indicates better impedance matching and minimal signal reflection

Low insertion loss ensures maximum signal transmission with minimal attenuation

Ensure the selected RF N connector meets the electrical specifications required by your system to maintain signal integrity.

5. Assess Environmental and Mechanical Requirements

Depending on the application, RF N connectors may be exposed to vibration, temperature extremes, moisture, or dust. Consider:

Operating temperature range and thermal stability

Vibration and shock resistance for industrial or transportation applications

Sealing and IP ratings for outdoor or harsh environments

High-quality connectors designed to withstand challenging conditions help prevent downtime and maintain reliable operations.

6. Choose a Trusted Manufacturer

Selecting a reliable supplier ensures consistent quality, compliance with standards, and technical support. CAZN Electronic specializes in industrial connectivity solutions, gradually becoming a key player in the domestic industrial connector sector. With expertise in multiple industries and strict adherence to international standards, CAZN delivers RF N connectors that meet high-performance and reliability requirements.

Conclusion

Choosing the right RF N connector requires careful consideration of frequency, type, material, electrical performance, environmental tolerance, and supplier reliability. By selecting connectors that meet both technical and environmental requirements, engineers can ensure efficient, reliable, and long-lasting RF or wireless systems.

Partnering with a trusted manufacturer like CAZN Electronic provides access to high-quality industrial connectors, expert guidance, and components designed to excel in demanding applications across wind power, transportation, automotive, and smart manufacturing industries.