Top Advantages of Heavy Duty Connectors in Automotive, Machinery, and Energy Systems

In modern industrial and transportation systems, reliable connectivity is critical. Heavy duty connectors play a key role in ensuring seamless electrical and signal connections across harsh environments, high-vibration conditions, and high-power applications. From automotive assembly lines to wind turbines, these connectors deliver the performance and safety that industries demand. This article explores the top advantages of heavy duty connectors, with insights from CAZN Electronic, a professional company specializing in industrial connectivity solutions.

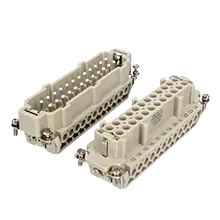

What Are Heavy Duty Connectors?

Heavy duty connectors are robust electrical connectors designed to handle high current, voltage, and mechanical stress. Unlike standard connectors, they are engineered for environments where vibration, moisture, dust, and temperature fluctuations could compromise conventional connections. They are widely used in industries such as:

Automotive: Engine control units, assembly robots, and power distribution

Machinery: Industrial automation equipment, CNC machines, and manufacturing systems

Energy: Wind turbines, solar inverters, and power distribution systems

CAZN Electronic produces heavy duty connectors that comply with international standards such as IEC, GB/T, and UL, ensuring quality, safety, and reliability in every application.

Key Advantages of Heavy Duty Connectors

1. Exceptional Durability and Mechanical Strength

Heavy duty connectors are designed to withstand extreme conditions. Their robust housings, secure locking mechanisms, and high-quality contacts resist vibration, shock, and mechanical wear. This makes them ideal for applications in automotive assembly lines, industrial machinery, and energy infrastructure, where reliability is non-negotiable.

2. High Current and Voltage Capacity

These connectors can handle high electrical loads, making them suitable for power-intensive applications like electric vehicles, high-speed trains, and industrial machinery. CAZN Electronic’s products are engineered to maintain stable connectivity even under demanding electrical conditions, reducing the risk of downtime or component failure.

3. Environmental Resistance

Heavy duty connectors are built to resist dust, moisture, chemicals, and temperature extremes. Many feature IP-rated protection, ensuring operation in outdoor, industrial, or high-humidity environments. This is particularly important for energy systems like wind turbines and solar arrays exposed to weather conditions.

4. Versatility Across Industries

With modular designs and multiple contact configurations, heavy duty connectors can be adapted to a wide range of applications. CAZN Electronic’s solutions serve industries including:

Wind Power: Connecting turbines, inverters, and control systems

High-Speed Rail: Power and data transmission in trains

Automotive Manufacturing: Robotics, assembly lines, and EV power systems

Smart Manufacturing & Traffic Systems: Reliable connectivity for sensors, actuators, and communication networks

5. Compliance with Global Standards

Heavy duty connectors must meet stringent international safety and performance standards. CAZN Electronic strictly adheres to IEC, GB/T, and UL certifications, ensuring that each connector meets rigorous electrical, mechanical, and environmental requirements. This compliance guarantees safe, reliable operation for critical industrial and transportation systems.

Why Choose a Professional Connector Manufacturer

Selecting a trusted manufacturer is key to ensuring the performance and longevity of heavy duty connectors. CAZN Electronic offers:

A wide range of industrial connectors designed for harsh environments

Expertise in customizing solutions for automotive, machinery, and energy applications

Advanced production processes that ensure consistency, durability, and precision

Compliance with international standards for safety and performance

Partnering with a professional supplier ensures that your systems remain operational, efficient, and safe.

Conclusion

Heavy duty connectors are indispensable in automotive, machinery, and energy systems. Their durability, high electrical capacity, environmental resistance, versatility, and compliance with international standards make them a cornerstone of modern industrial connectivity.

By choosing connectors from CAZN Electronic, businesses can rely on high-quality, professional solutions that enhance system reliability, reduce downtime, and support long-term operational success. In industries where precision and safety matter, heavy duty connectors are more than a component—they are a critical investment in performance and efficiency.